Kebony

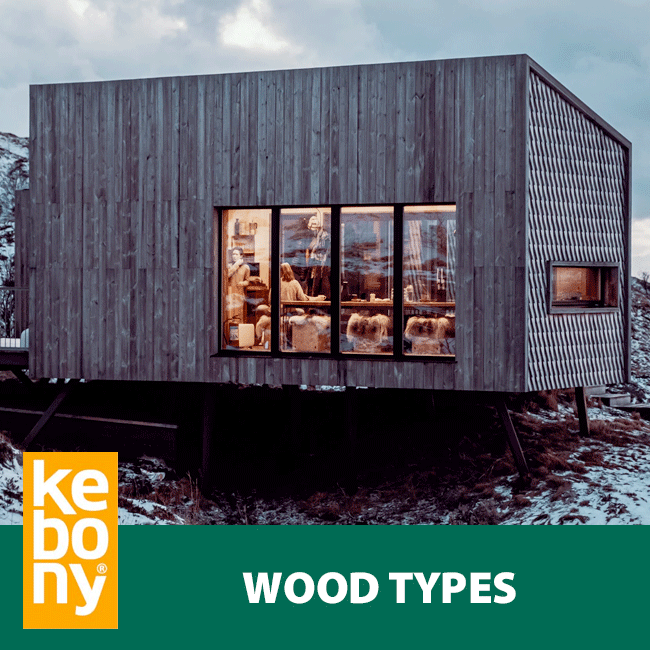

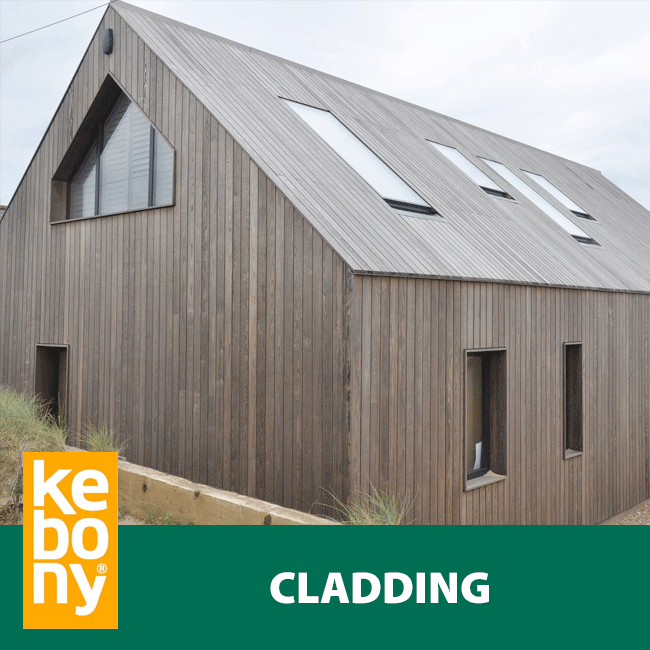

Headquartered in Oslo, Norway, Kebony is the leading global modified wood brand. Underpinned by proven and patented timber modification technologies, it produces an enhanced wood of superior quality that is both environmentally friendly and cost-effective.

From its production facilities located in Skien, Norway, and Flanders, Belgium, Kebony redefines standards in the timber industry and new possibilities for wood as a sustainable construction material. Kebony has sales and distribution across Scandinavia spanning into Europe, North America and the rest of the world.

The company has received numerous awards and accolades for its environmentally friendly technology and innovation, including being named a World Economic Forum Technology Pioneer, repeated recognition as a Global Cleantech 100 company, and a 2019 Building, Design + Construction Top 101 Products Reader’s Choice Winner.

Kebony Technology

Fully compliant with EU Timber Legislation, Kebony technologypermanently transforms sustainable wood species such as pine into finished products with characteristics comparable—and in some cases better-performing—to those of precious tropical hardwoods. This unique, patented technology is a process whereby sustainably sourced wood species are impregnated with furfuryl alcohol, which is derived from agricultural crop waste. With the addition of heat, the furfuryl polymer is permanently grafted into the wood cell wall, resulting in greatly improved durability and dimensional stability, making the wood strong and resistant to biological decay and harsh weather conditions.

Natural Mission

Through active innovation and forward thinking, we will continue to produce beautiful, long-lasting and environmentally friendly wood products. The company will promote and practice social responsibility to improve the environment in a way that builds a better future.

Edge Banding for Plywood (VARIOUS)

A narrow strip of material used to create durable and aesthetically pleasing trim edges when finishing carpentry. Edge banding is used to cover the exposed sides of materials such as plywood, particle board or MDF, increasing durability and giving the appearance of a solid or more valuable material.

Edge banding can be made of different materials including PVC, ABS, acrylic, melamine, wood or wood veneer and use various types of adhesives and glues for attachment.

Available in: Alder, Ash, Cherry, Mahogany, Maple, Red Oak, Rift & Quartered White Oak, Walnut, White Birch, White Oak & White Poly

FAU = FLEECE AUTOMATIC (NO GLUE)

PS = PEEL & STICK

FPG = FLEECE PREGLUED / IRON-ON

- Desc.

- Sizes

- Quote