Subscribe And Enjoy!

Product Updates,

Special Sales & More!

I don't want to see this anymore.

Softwood is wood from gymnosperm trees such as conifers. The term is opposed to hardwood, which is the wood from angiosperm trees. The main differences between hardwoods and softwoods is that the structure of hardwoods lack resin canals, whereas softwoods lack pores.

Hardwood lumber comes in thicknesses measured in quarters of an inch. 1″ lumber is called 4/4 (four quarters). 2″ lumber is called 8/4 (eight quarters).

Hardwood Grades:

FAS (First and Seconds) – The highest grade available, generally limited to Southern and Appalachian hardwoods due to minimum dimension requirements (6” x 8’). Though not required to be clear, FAS boards must be 83.1/3% clear or usable.

S&B (Select and Better) – The Northern hardwood equivalent of FAS. Basically the same tolerances as FAS, but allows for minimum board size of 4” x 6’. Most Northern hardwoods are graded using this format to accommodate the smaller dimension logs that result from an abbreviated growing season.

#1 Common – The grade below FAS and S/B. Generally used in the cabinet and furniture industry. A 1-Common board must be 66.2/3% usable. 1-Common lumber can be used in millwork, but should be limited to small profiles, or profiles that do not require long, clear pieces.

HARD MAPLE, CHERRY AND WALNUT IN MILLWORK:

Certain hardwoods require special attention when being quoted or used in architectural millwork, as they may have some undesirable characteristics that are allowed for in their respective grades.

White Hard Maple – Northern Hard Maple is generally desired for it’s mostly uniform white color. The grading format for White Hard Maple does not, however, require that a board be 100% white.

Cherry – North American Cherry has distinctive white to yellow sapwood. While generally not desirable in finished millwork, this sapwood is not considered a defect, and is therefore permitted in product milled from Cherry unless otherwise specified.

Walnut Prime yields at least 83-1/3% clear-face cuttings and 66-2/3% on the back. Minimum cutting sizes of 3” x 6′ or 4” x 3′

Black Walnut – Walnut characteristically has more natural defects than other hardwoods and, in fact, has it’s own grading rules to accommodate this. Walnut is a short, stocky tree that yields narrow, short lumber. It additionally has distinctly light sapwood that, while normally steamed to blend with the heartwood, is not considered a defect.

Softwood Grades:

CBTR Pine is a clear solid board cut derived from the C grade + Better grade.

STK (Select Tight Knot): Knots, burls and the occurring markings which are of consistent distribution and add to the attractive character.

Western Red Cedar (WRC): D and Better Clear grade lumber is defined by knots and other natural features that show the visual character of this grade.

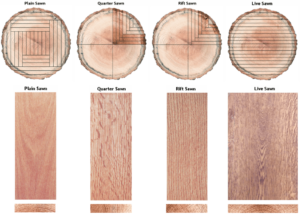

What is Sawn?

PLYWOOD:

Plywood is an engineered wood from the manufactured boards family which includes particle board and oriented strand board (OSB). It is made from thin sheets of veneer peeled from debarked wood. These thin layers, also called plies, are glued together in alternating right angles to create a cross-grain pattern. This pattern adds strength and stability that resists shrinkage and expansion caused by moisture.

Plywood is a popular choice in construction because of its strength and low cost. It is used in areas hidden from view that offer support such as floors, walls, roofs and garages in residential construction.

When used for roofing, plywood panels are covered and protected by other materials that keep the elements at bay, including roof felt, underlayment, flashing and shingles. When used in flooring, plywood creates a subfloor that supports hardwoods, tile and carpet floors.

Stainable and paintable plywood is ideal for shelving, cabinets and furniture. Outside the home, plywood can be transformed into fencing materials, packaging materials, scaffolding, sheds and shipping containers.

There are several common types of plywood:

Sanded plywood features face and back (top and bottom) plies that are sanded in the manufacturing process. It is used in places where it is visible, such as for cabinets, shelves and paneling.

Hardwood plywood is made from hardwoods like birch, maple and oak. The plies are glued at right angles to one another, making the plywood very strong and stable. It can be heavier than other types of plywood. Use hardwood plywood for furniture and anything that requires a strong load-bearing frame.

Plywood sheathing or structural plywood is designed for permanent structures. It is strong and inexpensive, but unfinished, and therefore not suitable for places where it will show. It should be covered by other types of materials. Use plywood sheathing for framing, beams, flooring and bracing panels.

Project plywood panels are ready-to-use, pre-cut plywood boards designed for quick and easy DIY projects. There are various types of wood, ply and plywood alternatives available. Use this for planned DIY projects when you know the measurements. It’s a great material for beginner DIYers.

Markerboard has plywood panels with a coated writing surface to use with dry erase markers only. It is ideal for craft tables or finished markerboards.

A ply refers to a layer of veneer used to create plywood’s various thicknesses. More ply creates a thicker and stronger board. Plywood has an odd number of plies and needs at least three plies. Although specialty plywood can have any number of plies above three, most plywood is categorized as 3-ply, 5-ply or multi-ply.

3-ply is one of the most common types of plywood. It is about 2- to 3-millimeters thick and is generally used indoors, since it looks more decorative than thicker plywood boards.

5-ply is a versatile type of plywood that is about 4-millimeters thick. Use it indoors or outdoors, but avoid using for framing permanent structures, such as a shed or a home.

Multi-ply is a catchall term for plywood with seven or more plies. This plywood is strong and durable enough for use in roofing, framing and other exterior, structural projects.

Tip: Plywood with fewer plies is weaker than a plywood with more plies, even if they have the same thickness.

The first patent for what could be called plywood was issued December 26, 1865, to John K. Mayo of New York City.

Plywood Grades:

NAUF is an acronym that stands “No Added Urea Formaldehyde”. NAUF products are specifically manufactured by the wood industry to eliminate urea formaldehyde from the bonding process. Urea-Formaldehyde is a reference to the type of resin that is used as a bonding agent in some types of plywood and composite wood panels.”

Hardwood plywood is a manufactured plywood panel made up of three or more layers, with a hardwood face species (like red oak, birch, walnut, maple and many more).

MDF or Medium-Density Fibreboard, is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibres, often in a defibrator, combining it with wax and a resin binder, and forming it into panels by applying high temperature and pressure. MDF is generally denser than plywood.

STAIN GRADE FACE: A & B (exception: WHITE C = stain)

PAINT GRADE FACE: C & D

PG1: PREMIUM PAINT GRADE

STAIN GRADE BACK: 1

MID GRADE BACK: 2 (can be stain or paint depending on the face)

PAINT GRADE BACK: 3

MILL OPTION BACK: 4

When choosing plywood or a plywood alternative, consider these features as well:

Choose the types of plywood you need for your projects based on where and how you’ll be using the panels.